Product Information

CFL-605RT

- Liên hệ để biết giá

Compact & Multi Cutting -Rapidly bringing ideas into shape-

The CFL-605RT supports material sizes up to A2 extra and has a variety of functions including eccentric, tangential, and reciprocating cuttings and creasing. It is designed with Mimaki’s well-established technology, and supports on-demand production by multiple functions, including cutting and creasing. The CFL-605RT delivers efficient sample and package production.

The multifunction plotter strongly supports digital on-demand production

- Eccentric cut

- Tangential cut

- Reciprocating cut

- Creasing

The combination of CFL-605RT and UJF-6042 achieves package fabrication on-demand

Use in combination with the UJF-6042 achieves on-demand production of the original goods by providing the whole production process, including printing onto goods and packages, and cutting of cushioning materials.

* UJF-6042 is sold separately.

Specifications

| CFL-605RT | ||

|---|---|---|

| Type | Flatbed cutting plotter | |

| Driving method | X/Y/Z/Θ 4 axes: DC servo motor | |

| Material holding method | Air suctioning by a vacuum unit | |

| Maximum media | 630 mm x 530 mm | |

| Cutting area | 610 mm × 510 mm | |

| Maximum cutting speed | XY: 423 mm/s (45° angle direction) Z: 30 mm/s | |

| Maximum downforce pressure | Eccentric cutter: 1,000 g / Tangential cutter and Creasing roller: 1,500 g | |

| Maximum media thickness | Reciprocating cutter: 10 mm / Tangential cutter: 2 mm *1 | |

| Maximum media weight | 10 kg (This is not one-point-load strength) | |

| Static accuracy |

Repeatability | 0.2 mm or lower (Material shrinkage is ignored) |

| Distance accuracy | Moving distance × ±0.2% or lower or ±0.1 mm or lower Larger value is applied |

|

| Original repetition accuracy |

0.1 mm or lower | |

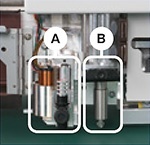

| A unit | Attachable tools: Eccentric cutter, Pen | |

| B unit | Attachable tools: Reciprocating/Tangential cutter, Creasing roller | |

| Command | MGL-IIc3 | |

| Certifications | VCCI class A, FCC class A, ETL UL 60950-1 CE Marking (Machinery directive, RoHS), CB, REACH |

|

| Interface | USB 2.0 (High Speed), RS-232C, Ethernet | |

| Noise level | 70 db or lower (The maximum level is generated while a reciprocating cutter or a vacuum blower is used.) |

|

| Operational environment | Temperature: 5 °C–35 °C, 35%–75% RH (Non-condensing) Guaranteed humidity range for an accurate operation: 12 °C–25 °C, 45%–65% RH (Non-condensing) |

|

| Power specification | Single phase AC 100–120 V/200–240 V, 50/60 Hz | |

| Power consumption | 500 W or lower | |

| Dimensions (W × D × H) | 1,320 mm × 1,045 mm × 1,100 mm | |

| Weight | 109 kg or lower (Blower, 23 kg, included) | |

Please note:

*1: An applicable range of cutting thickness may slightly vary depending on materials.

- Specifications are subject to change without notice (for technical improvements, etc).

- All trademarks or registered trademarks are the property of their respective owners.

Compact multifunction cutting plotter

CFL-605RT is compact but provides a wide range of functions including eccentric, tangential, and reciprocating cuttings and creasing. Ideal for package mockup production and small-lot package production.

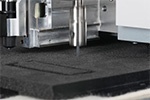

Reciprocating cutter for cutting cushioning material

Cushioning for packaging can also be cut with CFL-605RT. Thick materials are neatly cut by a vertical reciprocating motion. The reciprocating cutter is capable of cutting materials of up to 10-mm thickness.

Reciprocating cutter

(vertical reciprocating cutting)

The blade cuts thick materials by a vertical reciprocating motion. It is ideal for foam or cardboard cutting. In addition, the blade is capable of cutting a range of material thicknesses, from thin to thick, by precisely controlling the blade edge direction. (Before cutting, please place a felt mat on the cutting table under the material to hold it in place.)

【Optimum materials for a reciprocating cutter】

Cardboard, foam plastic board, and sponge

■Maximum vertical vibration rate: 3,000 reciprocating motions/min.

■Vibration stroke: 5 mm

■Downforce pressure: 1,500 g (Fixed pressure value)

■Maximum cutting thickness*: 10 mm (*Thickness varies depending on materials.)

Tangential cutter for thick material cutting

The blade is able to cut not only thick materials up to 2 mm but also thin films by controlling low and high downforce pressures precisely.

Tangential cutter

(Cutting materials by downforce pressure)

The blade edge is automatically and precisely controlled along contour cutting lines specified by the software. It is good for cardboard and foam board.

【Optimum materials for a tangential cutter】

Coated cardboard, reflective vinyl, rubber sheets, industrial materials, and F/G flute cardboard.

■Downforce pressure: 500–1,500 g (Optimum pressure varies depending on material)

■Maximum cutting thickness*: 2 mm (*Thickness varies depending on material)

Cutting and creasing with one compact plotter unit

The versatile CFL-605RT plotter is capable of cutting and creasing. It can be used on paper, PET as well as film.

Eccentric cutter

Maximum cutting thickness: 1 mm

Materials are properly cut with an optimal downforce setting from 30 and 1,000 g for optimum cutting.

Creasing roller

The roller creases materials and enables the creation of a perfect package. Downforce pressures are adjustable from 500 to 1,500 g depending on the material.

Accurate cutting by reading register marks

A sensor reads register marks on the material for precise cutting.

Offering various tool combinations to meet a range of work demands

Depending on application, different tools for each unit can be switched in for optimum cutting.

A unit / B unit

【Adjustable tools for each unit】

[A unit]

Pen/Tangential cutter

[B unit]

Reciprocating cutter

Tangential cutter

Creasing roller

*Tools need to be switched manually by users.

A vacuum suction system reduces lifting of material during operation by holding the material in place.

Lightweight or thin materials tend to move or lift during cutting; therefore, CFL-605RT offers a combination of features to prevent this problem. A compact built-in vacuum unit holds the material in place during reciprocate cutting. An adsorption sheet (SPC-0787) put on top of the material to be cut enhances vacuum suction by reducing air flow through the material, and the adsorption sheet is easily unrolled from the left side of machine.

*Please place felt mat 605 (SPC-0785) on the cutting table during reciprocate cutting.

*Please tape four corners of any material that cannot be held securely by the vacuum unit.

* An adsorption sheet (SPC-0787) is sold separately.

Best combination:

Easy mock-up production in combination with UV inkjet printer!

Conventionally, there are many work processes involved in creating packaging for a product. You might ask an outside contractor to create the package; however, it would take longer to complete the work because of misunderstandings, distance, time differences, etc. The combination of CFL-605RT and UJF-6042* offers a total solution, not only for printing on a product but also for the design and creation of product cushioning and packaging. This combination delivers effective high-mix low-volume production and significantly shortens the lead time for prototype creation and small-lot production by on-demand fabrication.

*UJF-6042 is sold separately.

What is the flatbed printer UJF-6042?

UJF-6042 is a LED UV curing inkjet printer capable of printing on objects as well as on packaging materials up to A2 size.